Mã sản phẩm: C5200-240

Trạng thái: Có sẵn

Xuất xứ: Environmental Express, USA

| Materials of Construction | PTFE-coated aluminum block, powder-coated steel housing |

| Power (VAC) | 240 VAC, 7.5amps |

| Power (Hz) | 50 |

| Item# | Description | |

| C5201-240 | MicroBlock-V, Block Only, 240V | |

| C5012 | MicroBlock-V Cyanide Reaction/Absorption Flask, each | |

| C5216 | Cyanide Distillation Head, Style 2, each | |

| C5210 | Cold Finger for Distillation Glassware, each | |

| C5217 | Absorption Impinger for Cyanide, each |

7.0 PROCEDURE - EPA method 335.4

7.1 Pipette 50mL of sample or an aliquot diluted to 50mL with reagent water into the MicroBlock Reaction Flask.

Add a pinch of boiling chips. For solid samples weigh 1g or less to the nearest 0.01g, dilute to 50mL and

add boiling chips.

7.2 Pipette 50mL of 0.25N NaOH into the Absorption Flask. If using the Snip & Pour concentrate pour the entire 10mL

of the 1.25N NaOH into the absorption flask. Dilute to 50mL using DI Water. Refer to the schematic (Figure 2,

page 10) for the appropriate placement positions and flexible tubing connections to cool the Cold Finger with

running tap water. All air/vacuum valves are in the OFF position.

7.3 Repeat steps 7.1 and 7.2 for all samples to be distilled up to a maximum of 10.

7.4 Position the Cold Finger and Absorber Impingers.

7.5 Turn tap water ON after assuring all tubing connections are firmly placed. A water flow rate of 50 to 60 gallons

per hour is required.

7.6 Turn ON the vacuum and slowly adjust each valve to provide an air flow bubble rate of several bubbles per second

for each position as viewed in the absorption vessel.

7.7 If nitrate-nitrite is known to be present add 5mL of sulfamic acid reagent through the reagent inlet. Allow the air

flow to mix for several minutes.

7.8 Slowly add 5.0mL of 18N sulfuric acid though the reagent inlet.

7.9 If iron cyanide complexes are known to be present add 2.0mL of magnesium chloride reagent. If excess foaming

occurs, add an additional 2mL. Allow a few minutes to mix.

7.10 Turn the heat ON and set the temperature of the heating block to 150°C.

7.11 Set the timer for 1 hour.

7.12 Timer will automatically turn OFF power to the heater block at the pre-selected time.

7.13 Disconnect the Distillation Head and Absorption Impinger by separating the Slip Connector. Turn air/vacuum valves

to the OFF position. Repeat for each sample position.

7.14 Allow the tap water to continue circulating through the Cold Fingers which will cool the heater block more rapidly

in preparation for the next run.

7.15 The distilled cyanide in the 0.25N NaOH solution is now ready for analysis.

7.16 Immediately after the run is finished, place the Absorption Impinger in distilled water. Do not let the impinger dry

out since the NaOH may clog the frit.

7.17 If the frit becomes clogged, clean with concentrated HCl using an ultrasonic bath. If this procedure is not successful

use aqua regia.

7.18 After use clean exterior surfaces with a damp sponge. For acid spills sponge with a diluted solution of sodium

carbonate followed by distilled water.

Sản phẩm cùng loại

Bộ phá mẫu HotBlock SimpleDist 12 vị trí, ống 50 mL; 240 VAC, Hãng Environmental Express, Mỹ

Mã sản phẩm: Environmental Express, Mỹ

Trạng thái:

Bộ chưng cất MicroBlock-R đồng thời 10 mẫu Ammonia (0.01 - 2 mg/L), Hãng Environmental Express

Mã sản phẩm: Environmental Express, USA

Trạng thái:

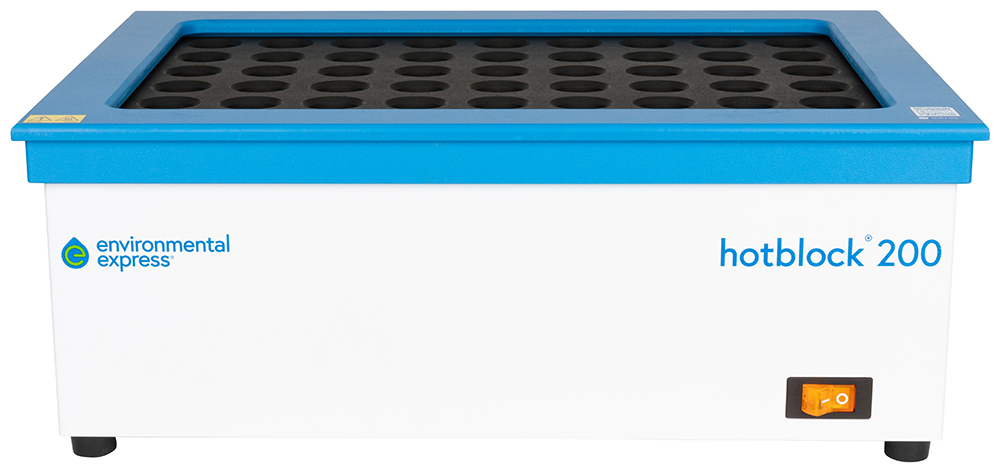

Bộ phá mẫu HotBlock 200 Series, 240 VAC, Hãng Environmental Express, Mỹ

Mã sản phẩm: Environmental Express, USA

Trạng thái:

Bộ phá mẫu HotBlock 150 - 35 vị trí, ống 100 mL; 240 VAC, Hãng Environmental Express, Mỹ

Mã sản phẩm: Environmental Express, Mỹ

Trạng thái:

Bộ phá mẫu HotBlock 150 - 96 vị trí, ống 15 mL; 240 VAC, Hãng Environmental Express, Mỹ

Mã sản phẩm: Environmental Express, Mỹ

Trạng thái: